General Impressions

It was quite an experience riding under full load. On level ground the extra weight does not reveal itself. With the correct gear selection, pedaling is easy and comfortable. However, on even a slight incline you can feel it. I am learning that it is important to not ride in too high a gear. It puts stress on the knees and uses energy at a more rapid rate than is really necessary.

Looming in the back of my mind is the challenge that will come in the form of daily rides of this nature. The only rest I will receive is the few hours at camp between rides. Recovery time will be less. I will continue to step up training in preparation. I did experience some knee pain, but it was manageable. At night while resting I could feel a few muscle cramps trying to inch their way into my hamstrings. I have been watching the Tour de France, where the riders complete 124 miles under full pressure daily for three weeks. I tell myself, “I can do that.” My wife raises a brow and questions me as to whether I really want to ride 865 miles.

“You’ll miss me.” she says. She nearly put her foot down over the incident you will read about later in this post.

Traffic was particularly gnarly on the second half of the loop. There are tons of 16-wheelers on Jurupa Street which caused me to change riding strategy quite a bit. I think this is why it took longer to ride the 52 miles than I thought it would. Also an unscheduled stop at Farmer Boys for a burger did not help either. The food I was carrying would have been sufficient. I will not make that mistake again.

As expected the last two miles into the camp site were the hardest. On the final half mile with it’s 10% to 13% grade I had to rest for 30 seconds for every 2 minutes of riding. My legs were very spent by then.

In the morning the climb out of camp was also very steep – at least 10% and probably more in some sections. Having fresh legs was a benefit and I used my lowest gear almost the entire way, as time was not a factor. I was only 8 miles from home.

All-in-all it was quite an achievement. With a bit more training I feel I will do well on the PCTA. I am definitely glad I did it, because I learned quite a bit. I have broken down the information into general categories for easier digestion.

Equipment

Panniers

The Arkel Panniers swallowed up everything with room to spare. Compartments are handy and those giant zippers are just the ticket. One note however: anything that needs to remain cool should not go into the top compartments. They get really hot in direct sunlight. Electronics, batteries, CO2 cartridges, or anything else that may be subject to heat should not be stored there.

Tent

The Quarter Dome T2 Plus by REI is very light and packable. For assembly one needs to at least the watch the video on the REI web site more than once to make sure all goes smoothly. Check me out in the video below. I had the orange poles on wrong side of the large main pole, but once I figured that out, the tent went up fairly easily. The fabric of the tent seemed a bit overly tight over the poles. I had to wrestle with the tabs a bit, but nothing ripped or tore. I would recommend getting a footprint to go under the tent.

The rain fly was easy to install, but by morning, on even a warm night, there was more than a little condensation on the underside of the it. I had to make sure this was wiped dry before folding it away. Since the fly is totally waterproof, I don’t think anything can be done about this. Humans exhale water vapor when they sleep. I did have both ventilation tabs open.

As you know, nothing ever packs back to the same small size it was when it came from the factory. For some reason the tent poles seemed too long to go back into the tent’s stuff sack. The tent body, fly, and footprint went in with room to spare. I ended up placing the poles into the tall sack on the back of the left Arkel pannier, which is designed to hold such items. Problem solved.

Camel Bak Water Bladder

This will not make the trip. It fits very nicely into the large compartment on the Arkel pannier, and the sipping tube is plenty long enough for handy use. The problem is that it is not insulated. Ice melts quickly. The water that remains in the sipping tube between drinks heats up to hot.

The bladder does not dry out quickly which could lead to mildew inside the bag. Now you have to use tablets to clean the bladder and thread a drying tool down the tube to dry it out. Too much work!

ExPed Down Mat Sleeping Pad

This was a dream piece of equipment. It almost self inflates, but some pumping is required. The pump is integrated into the design of the mat. You simply open that valve, place one hand over the opening and press down on the pump, with both hands. It inflates in about two minutes. In inches the size is 77.5 long, 26 wide, 2.8 deep. The 26-inch width was plenty for me.

It was very comfortable. During the night it never lost any air. The down inside the mat insulted from the cold ground underneath. Repacking was a bit fussy. It’s difficult but not impossible to get all of the air out of the mat. The release valve is one-way. Air gets pushed out, but cannot reenter. It took two tries to finally get it back into its stuff sack. It’s worth every expensive penny.

Insulated Hydro Flask (1.9) Liters

I wrestled with this purchase because this item was not cheap – $49 dollars at REI, but am I SO glad I bought it. I filled it with water and ice at 7:30 am. By 8:00 pm the same day the ice was melted but the water was ice-cold and stayed that way the rest of the night. My wife bought me up more ice at the camp site that evening, which I put into the flask. It is now 12:05 pm the next day and the ice still has not melted in the flask. This thing works fantastically. Best of all it fits like a glove into my Radical Banana Pannier. It’s not as handy as a Camel Bak sipping tube, but it’s reachable, and ice-cold water when you want it is a real treat. It’s one of my best purchases.

Speaking of ice, I did take a small canvas covered lunch bag which was insulted and lined with plastic. I used it as a small ice chest. I was very happy I decided to take this along. Ice was kept in a plastic bag inside the single large compartment. Cold oranges and apples are very refreshing on the road. When the ice melted inside the plastic bag I had another source was refreshing ice cold water.

Clothing

All clothing choices I have made seen to be a good ones. However, jeans are not going. They are uncomfortable for riding, and one pair weighs 2.2 lbs. all by itself dry. Also they are not water proof. Wet jeans must really be heavy. I’ll see about getting pants made of lighter fabric.

I may leave my extra riding jacket home also. It’s versatile, as the sleeves zip out, but it’s water-resistant, not water proof. I also don’t like the high collar on the back of my neck. I think my rain jacket will provide better warmth if I need it.

I need at least two long-sleeved riding shirts made of wicking material. I’ll pick those up at Walmart for $8.

Electronics

Both my GoPro Camera and my iPhone ran out of power by the end of the day. Actually that time ended up being well over 10 hours which is pretty good. I turned the camera off between every 30-second movie shots which helped preserve battery life. All movies were taken from my helmet mount, which I don’t think I will use. The resulting video is enough to make you sick with its shakiness. I will devise some sort of neck-worn strap that will allow for easy access to the camera.

The iPhone suffered a over-heat outage during the day. It was in a frame-mounted bag under a plastic cover for access. Due to the heat of the sun and the fact that it was running two applications most of the trip, it simply overheated. 10 minutes in the ice-chest solved the problem. This was another instance where I was glad I brought a small ice chest.

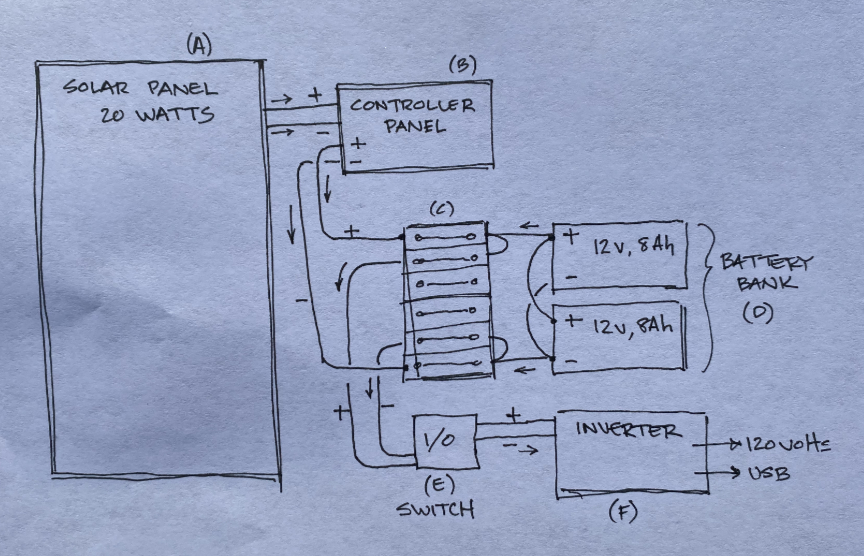

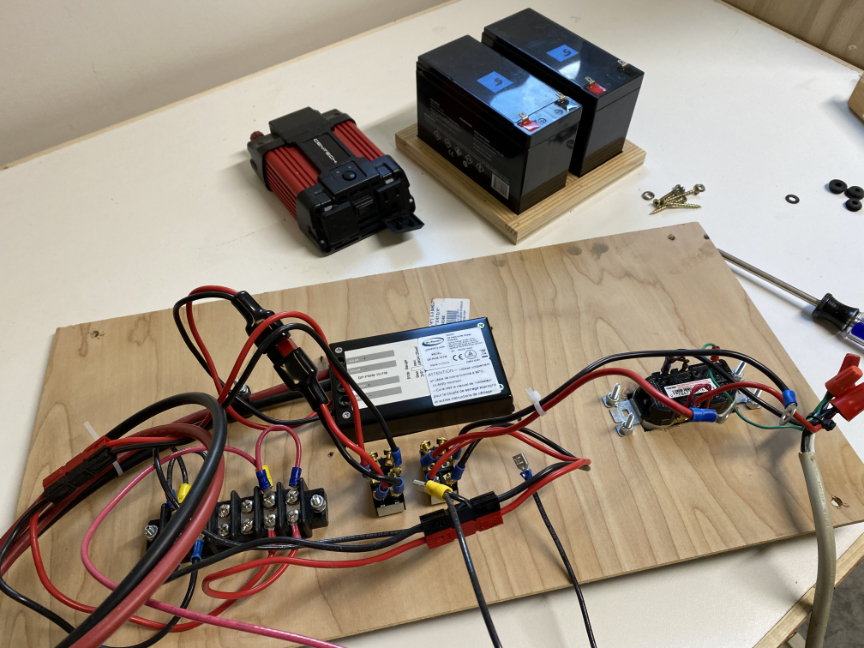

I plan to take a small solar panel with me on the trip. I will place it under the mesh of one of my Arkel panniers where it will charge during the day. At night it will be used to re-energize both the iPhone and the GoPro. I’ll let you know which one I decide on.

My Cateye Micro Wireless Speedometer locked up during the ride and stopped recording data. It was the second time this had happened. Research revealed that a Blue Tooth enabled iPhone speaking to a wireless heart rate monitor or other similar equipment such as a Wahoo speedometer interferes with the Cateye. On the tricycle these devices are in close proximity and there was simply too much Blue Tooth broadcasting and receiving going on between the devices.

Once the iPhone is not broadcasting the Cateye works properly. I could use the iPhone only but that would require that it run either the Strava application or the Wahoo application. Running either application would be only partially useful as there is no cadence hardware installed on the TRIcon. Plus using the iPhone would require leaving the screen on full time. That would quickly evaporate energy reserves.

Conclusion: my Wahoo heart rate monitor will be staying home. I’ll run the Strava application to document the mileage. The Cateye should work fine. Hey, a few more grams of weight will be saved.

Additional Stuff

Some things that I don’t have now, I will have to acquire are:

- a small chamois for drying that rain fly.

- flip-flops for the shower; I’d rather not get my Keens wet.

- small cloth ice-chest.

- two long-sleeved riding shirts.

Bad News

The Tricycle

Take a look at the before and after pictures of the underside of the TRIcon for a clue.

Before – unmarred, nice and new.

Here’s the after shot.

Note the scuff marks

What happened? Long-story-short: the two bolts that hold the handle bars to the steering column loosened to such an extent that the entire handle bar assembly disengaged itself. I was literally holding the bars in mid-air with absolutely no ability to steer. I had to physically steer by grabbing the left front fender to a avoid the curb on my right, while breaking with the right hand with brakes that thankfully still operated. Imagine steering by turning the front left fender to the left while braking with only the right caliper which causes your rig to turn right. It was a move orchestrated in skillful panic mode.

Thank you Lord Jesus I was not on a 29 mph descent on some mountain road. I may have not have been writing this article right now. That was scary. I won’t go as far to call it a design flaw, but I will contact AZUB about the situation, which needs addressing before someone gets seriously injured or worse. Lesson learned: check all bolts frequently, especially the ones that may directly affect the operation of the bike. I have already found a loose bolt on one of the disc brake calipers and tightened it up recently. There is no front suspension on the TRIcon which means road vibrations make it through to the frame more easily than a rig with a suspended front end. Things vibrate loose. Check your nuts and bolts.

I have since removed the two offending bolts, dipped them in Loctite and reinstalled them. I have also installed a rubber plug into the open end at the bottom of the steering column. It has a large washer covering the diameter. The rubber expands into the opening by turning a bolt in the center of the plug. Even if the two screws loosen again the rubber plug will keep the handle bars in place. See photos of the fix here.

The second problem was not as catastrophic. The rack on which the Arkel panniers sit moves closer to the rear axle when the suspension is compressed, as does the rear fender. During a jolting from uneven pavement the wire support rods on the right side popped loosed from their support, which caused the rear fender to jump into misalignment, which allowed the metal clips that attach to the fender to rub hard and grindingly against the rear wheel. I noticed a nice spray or rubber shrapnel on the chain stays near the rear tire.

I think this entire situation was caused by a combination of the 35 lbs. of weight on the rear rack and having the pre-load set too low on the rear shock. I will torque up the pre-load on the shock. The entire situation did make me seriously reconsider the possibility of the trailer once again. Maybe it’s better not to have too much weight on the actual tricycle. I will invest in the purchase of the smallest torque wrench I can find to help keep those bolts tight. Ugh, that means extra weight.

Shifting at the front chain set and derailleur was a bit off due to cable stretch. I made an adjustment which helped, but it’s not 100% yet. I have to complete a nifty double, trigger/thumb move to get down smoothly to the middle chain ring. Getting to the smallest chain ring is still a problem. I’m working on that.

Conclusion

In spite of the mishaps and sore muscles I am very glad I took the ride. I now have first hand experience on what to look out for and how I may actually perform on the trip. I will take another loaded ride before arrival time of the PCTA.

Happy trails,

David